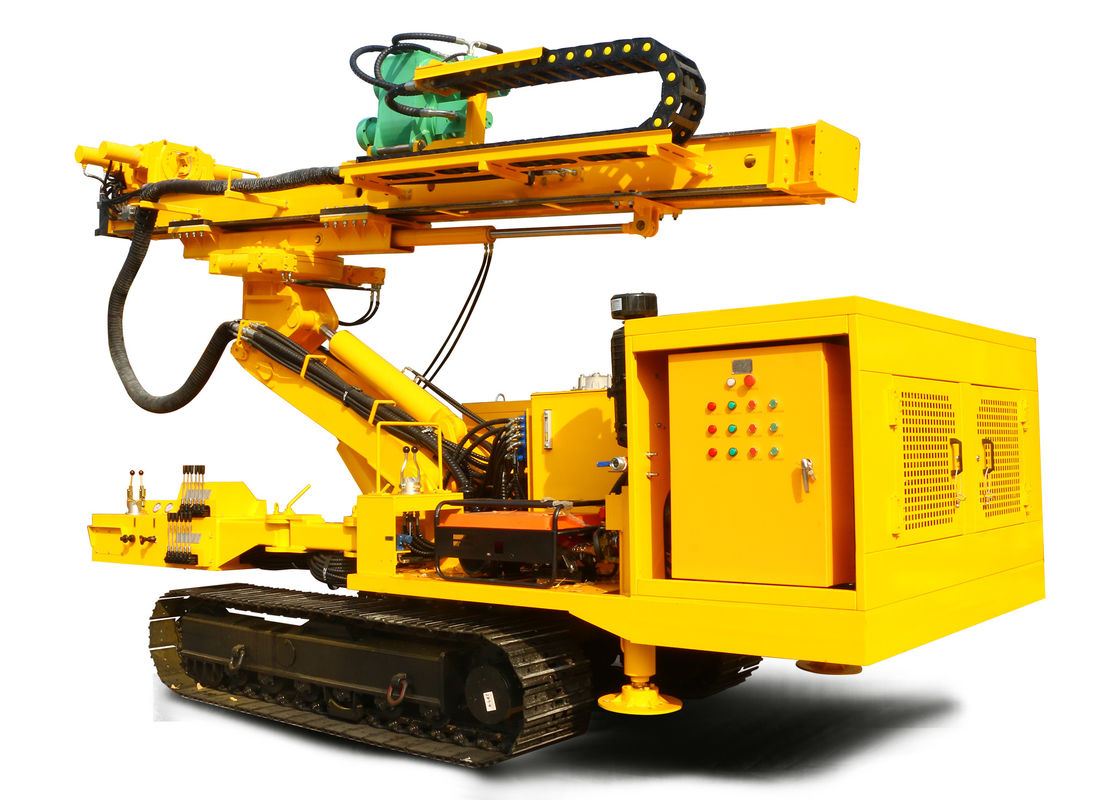

ZML160 Anchor drilling machine multifunctional crawler type drilling rig Drilling rig anchors

It is widely used in fields such as construction, highways, railways, water conservancy, electric power, tunnels, foundation pits, slopes, and military engineering.

Suitable for rock drilling in drift, egg, gravel layers, and layers covered by fractured and strongly weathered rocks, it can particularly demonstrate its efficient and stable performance. It can quickly and efficiently drill through complex formations and has broad application prospects in various geotechnical anchoring projects.

Technical specifications

| Power |

ZML-160 electric type |

engine |

55(Kw) |

| ZML-160 diesel type |

diesel |

74(Kw) |

| ZML-160 double power |

engine |

55(Kw) |

| diesel |

74(Kw) |

| ZML-160 electric work diesel walk |

engine |

55(Kw) |

| diesel |

37(Kw) |

| Power head |

Hole diameter |

90~250(mm) |

| Hammer |

CIR,DHD |

| Rock broken way |

percussion-rotary |

| Hole depth |

20-120(m) |

| Drill rod type |

Φ76/Φ89*1500/2000/3000 |

| Power head rotary speed |

35-70(rpm) |

| Power head max torque |

8000(N.m) |

| Power head max stroke |

3500(mm) |

| Max pulling force |

80(KN) |

| Whole machine |

Dimension |

6600*2000*2700 |

| Air consumption |

9~22(m3/min) |

| Drill angle |

0-360(°) |

| Rotary angle |

360(°) |

| Vice stroke |

1000(mm) |

| Rated pressure |

25(Mpa) |

| Climbing ability |

≦ 25(°) |

| Horizontal height |

3014mm |

| Weight |

About 8500kg |

Main features

Dynamic system

The whole machine can replace different power heads(DTH, top drive, coring) according to construction needs, making construction more convenient, reducing costs, and doubling production;

Rotating arm structure

By adopting a rotary arm structure, the operating range after one positioning is greatly increased. The drilling arm can rotate about 360 °, achieving any angle construction;

Control costs

By using pilot valves and variable piston pumps with load feedback systems, it has the functions of power protection and pressure cut-off. While effectively adapting to the total flow demand of various executing components, it achieves the best power matching under different working conditions and maximizes energy conservation;

Security measures

When drilling, the wind and water linkage system is used to reduce the large amount of dust generated during tunnel construction. While drilling, the crushed stones are washed out of the hole through high-pressure water, reducing the problem of sticking during drilling, achieving the goal of rapid drilling, improving work efficiency, and reducing construction costs;

Pipe shed construction

Both single rod drilling and drilling with casing can be used. When the geological situation is complex and there is collapse, the casing construction method can be adopted, which means the outer casing and inner drill rod drill to the required depth at the same time. Firstly pull out the inner rod, then pull in the steel pipe, finally pull out the outer casing;

Emergency rescue

During the construction process, in case of danger, geological exploration, geological improvement, and support operations in the danger zone can be quickly completed. If the underground space is obstructed by collapse, casing operations can be used to quickly transport air, water, and other rescue materials to the trapped personnel;

Company Overview

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!